Jimmy SongSNHS-snackbitarKl. 16:38 den 26 december 2022, Taiwan, Kina, Kina

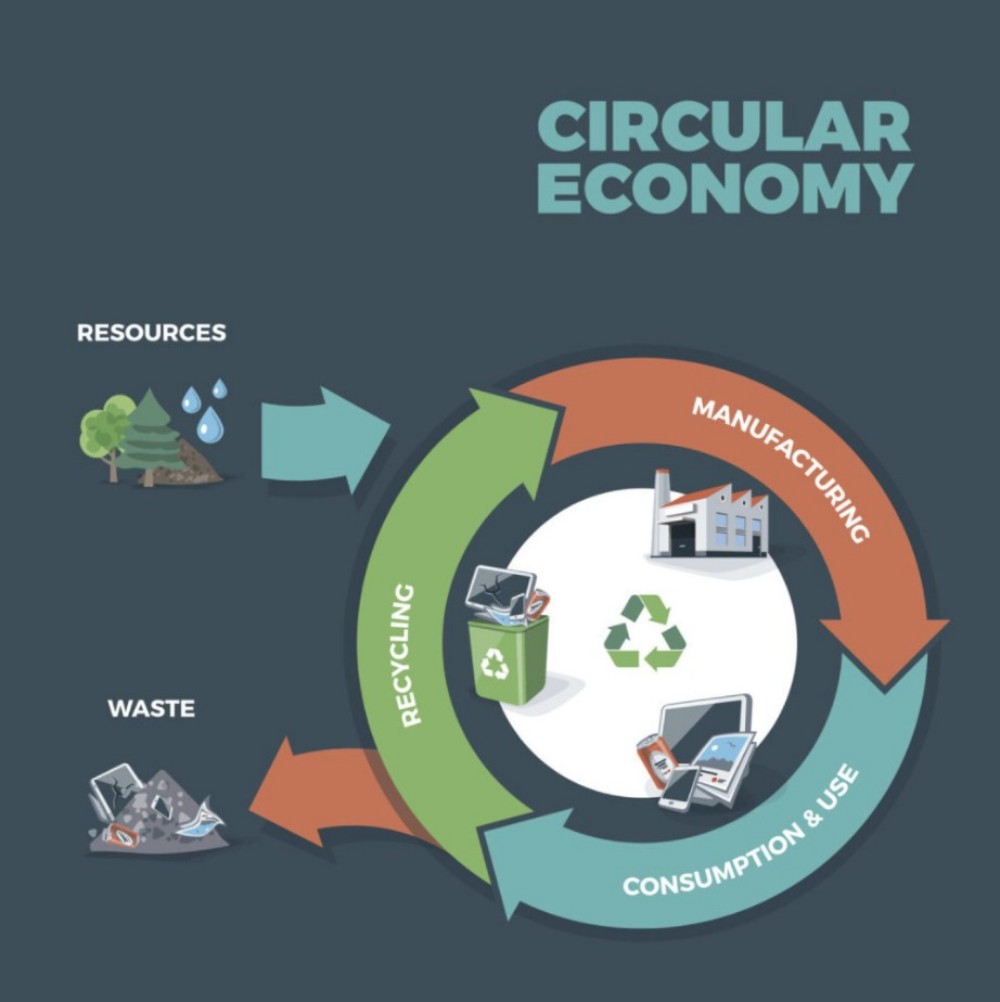

Additiv tillverkning: 3D-utskrift i den cirkulära ekonomin

Introduktion

Det populära talesättet ”Ta hand om landet så tar det hand om dig. Förstör landet så förstör det dig” illustrerar vikten av vår miljö. För att bevara och skydda vår miljö från ytterligare skada måste vi fokusera på att utveckla hållbarhet. Vi kan uppnå detta genom att använda en cirkulär ekonomi med hjälp av additiva tillverkningsprocesser (AM) istället för konventionella tillverkningsprocesser (CM) (Velenturf och Purnell). AM – allmänt känt som 3D-utskrift – minimerar avfall, använder miljövänliga material och minskar energianvändningen, vilket potentiellt gör det till nyckeln till en miljömässigt hållbar framtid.

Minimerar avfall och föroreningar

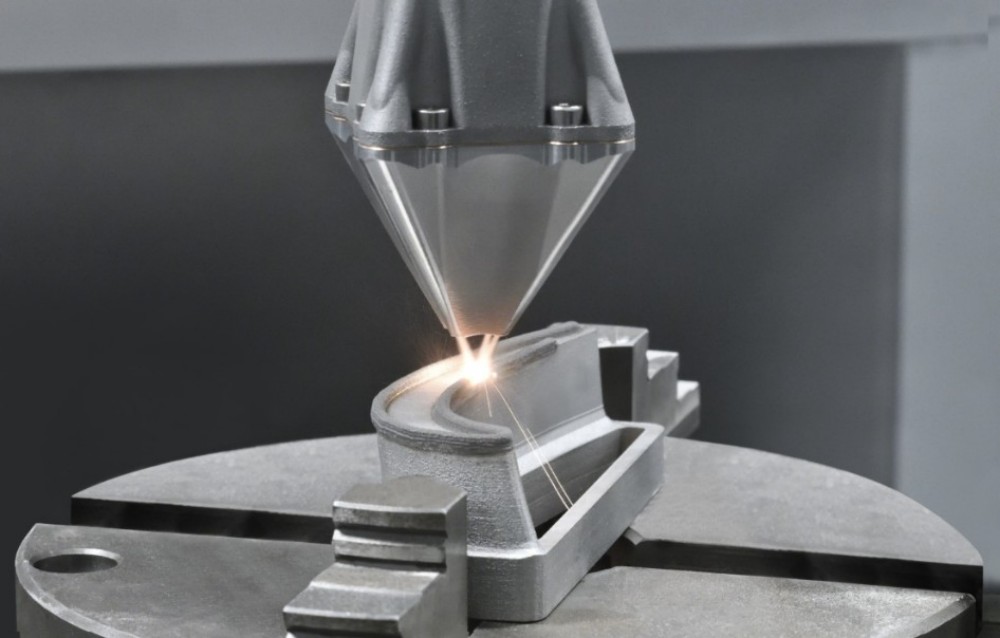

Färre råmaterial slösas bort och mindre föroreningar produceras när vi använder AM (amylalkoholbaserad material) framför CM (kompositmaterial). Enligt professorerna MR Khosravani och T. Reinicke vid universitetet i Siegen ”möjliggör [amylalkoholbaserad material] minimalt avfall i tillverkningsprocessen eftersom alla delar av modeller, prototyper, verktyg, formar och slutprodukter tillverkas i en enda process” (Khosravani och Reinicke). Eftersom allt tillverkas lager för lager, från botten till toppen, kommer 3D-utskriftsmaskinen endast att använda det material som krävs för den slutliga komponenten och mindre stödstrukturer. Till skillnad från traditionell tillverkning tillverkas produkter utan behov av montering i AM. Detta innebär att de växthusgaser som vanligtvis släpps ut under transportprocessen undviks, vilket sänker föroreningsnivåerna.

Energibesparing

Förutom att minska avfall och använda miljövänliga material är AM mer resurseffektivt för industrier. AM maximerar energieffektiviteten samtidigt som det minskar bränsleförbrukningen under tillverkningen (Javaid et al.).

Dessutom tillkännagav Vita huset att ”Eftersom additiva teknologier bygger från grunden snarare än att subtrahera material som sedan skrotas, kan dessa teknologier minska materialkostnaderna med 90 procent och halvera energianvändningen” (Vita huset). Om alla industrier som kan ersätta sin nuvarande tillverkningsprocess med AM-processen gör det, skulle vi vara mycket närmare att uppnå hållbarhet.

Slutsats

Ekologisk effektivitet är hörnstenen i hållbarhet, och minskningar av energianvändning och avfallsproduktion kan leda till betydande stopp i den globala uppvärmningen (Javaid et al.). Om mer tid och resurser investeras i forskning och utveckling av AM kan vi äntligen lyckas skapa en fungerande cirkulär ekonomi.

Publiceringstid: 1 april 2025